Today, turbo lag isn’t the blight on power delivery that it was during the infancy of the technology in cars in the 1970s and ’80s.

But as long as a centrifugal air compressor is driven by exhaust gases, there will be a delay in throttle response no matter how highly developed the system.

The solution, of course, is easy. Stick with a big naturally aspirated engine, or adopt a crank-driven supercharger. We’ve nothing against a big blower, however there’s something appealing about harvesting otherwise wasted exhaust gas energy and using it to boost engine power output, which is exactly what a turbocharger does.

Atmo power, meanwhile, is fine in a high-performance car. But motoring mainstream (even the supercar) is downsizing, with turbo boost making up for engines’ smaller capacities.

The trouble with this approach in a conventional small car that has adopted, say, a 1.4-litre turbo in place of an atmo 2.0-litre is that the resulting lag, however slight, can range from a disappointing dilution of crisp throttle response to an outright urban annoyance.

The other side of the coin is that there’s something enthralling about an early turbocharged car, with its delayed throttle response serving to underscore the shove in the back when it finally arrives. The 1980s Group A Ford Sierra RS500s had this characteristic in the extreme.

The other side of the coin is that there’s something enthralling about an early turbocharged car, with its delayed throttle response serving to underscore the shove in the back when it finally arrives. The 1980s Group A Ford Sierra RS500s had this characteristic in the extreme.

Old-school turbo tragics aside, the world seems to be aligned to the belief turbo lag is a bad thing. And Audi has an answer so simple it is astonishing no-one has brought it to market until now. Basically, an electric motor is used to spin a supplementary air compressor to fill the low-rpm boost hole – and therefore the engine’s torque hole – that a conventional exhaust-driven fan can’t.

In the background, a 48 volt electrical system provides the power needed to spin an electric motor-driven centrifugal compressor in a fraction of a second. The compressor boosts the engine’s exhaust-driven turbo (the smallest of them, if it’s a sequential set-up) to provide supercharger-like shove from little more than idle speed.

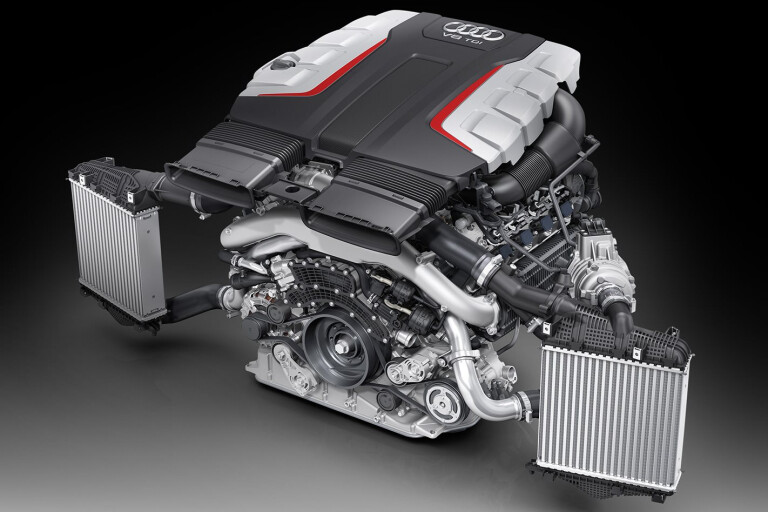

In the first road-going application of the system – in Audi’s upcoming twin‑turbo 4.0-litre V8 SQ7 super-SUV, due third quarter of 2016 at an estimated $180K – you get 900Nm at 1000rpm, with 7.4L/100km official economy. Wow!

The system takes the turbocharger’s something-for-nothing appeal to a new level, because it draws its energy from lithium-ion batteries charged using brake energy regeneration. You’re getting free boost from energy that would otherwise be wasted as heat in the brakes.

The system takes the turbocharger’s something-for-nothing appeal to a new level, because it draws its energy from lithium-ion batteries charged using brake energy regeneration. You’re getting free boost from energy that would otherwise be wasted as heat in the brakes.

Incidentally, the electric ‘turbocharger’ isn’t actually a turbo, because that name technically refers to an exhaust-turbine-driven compressor. Audi calls its unit an electric-powered compressor (EPC) and the system e-boost.

Why it took the automotive industry so long to engineer the electro-compressor for production – and why Audi saw fit to debut it on a porky SUV – remain question marks, but what’s certain is the tech is set to become increasingly common on future high-performance cars.

Audi’s ‘e-boost’: 5 steps to energy redeployment

1. Charging

Brake energy is harvested from slowing of the car – rather than wasting it as friction-derived heat in conventional brakes – and stored in lithium-ion batteries. Some cars use such systems, but Audi’s SQ7’s e-boost technology converts this chemical energy into boost via an electric compressor.

2. Elec-tricks

A 48 volt electrical system is one of the fundamentals of the e-boost system. It provides up to 13kW to quickly spin the 7kW electric motor-driven compressor up to speed. Audi says it hits 70,000rpm (therefore boost) in 250 milliseconds.

3. Loaded gun

The electric compressor preloads the engine’s turbo with boost – on the SQ7’s V8, it pressurises the smaller of two sequential exhaust-driven turbos – to kick off the 900Nm peak torque plateau from just a few hundred revs above idle. Audi claims 0-100km/h in just 4.8sec.

4. Top end

Traditionally, an engine’s turbo would be sized to suit the whole power band. But with the EPC unit (and the smaller sequential turbo) taking care of bottom-end response, the main turbo (or turbos) can be sized with less focus on throttle response and more on peak power.

5. Day-to-day?

Downsides? Few, except weight: EPC adds about 20kg. It would perhaps be more beneficial on a regular passenger car than a hi-po one but the system – at least for now – adds cost, so expect to see it on more weapons-grade machinery before it’s adopted for city cars.

Really hot stuff!

Really hot stuff!

Soaking up excess heat

THE SQ7 will be the first production Audi to feature the e-boost system. However, the tech was previewed on Audi TT Turbo and RS5 TDI concepts and features in the Ingolstadt brand’s R18 e-tron quattro LMP1 car.

The endurance racing machine takes energy harvesting to a new level in the pursuit of efficiency. As well as a brake-energy regeneration system, the R18 e-tron’s conventional turbocharger is connected to a system that lets it recover thermal energy (heat) from exhaust gas the turbo can’t use (when the engine has hit peak boost).

The energy harvested from both the braking and exhaust-gas systems can be redeployed as electric turbo boost.

COMMENTS